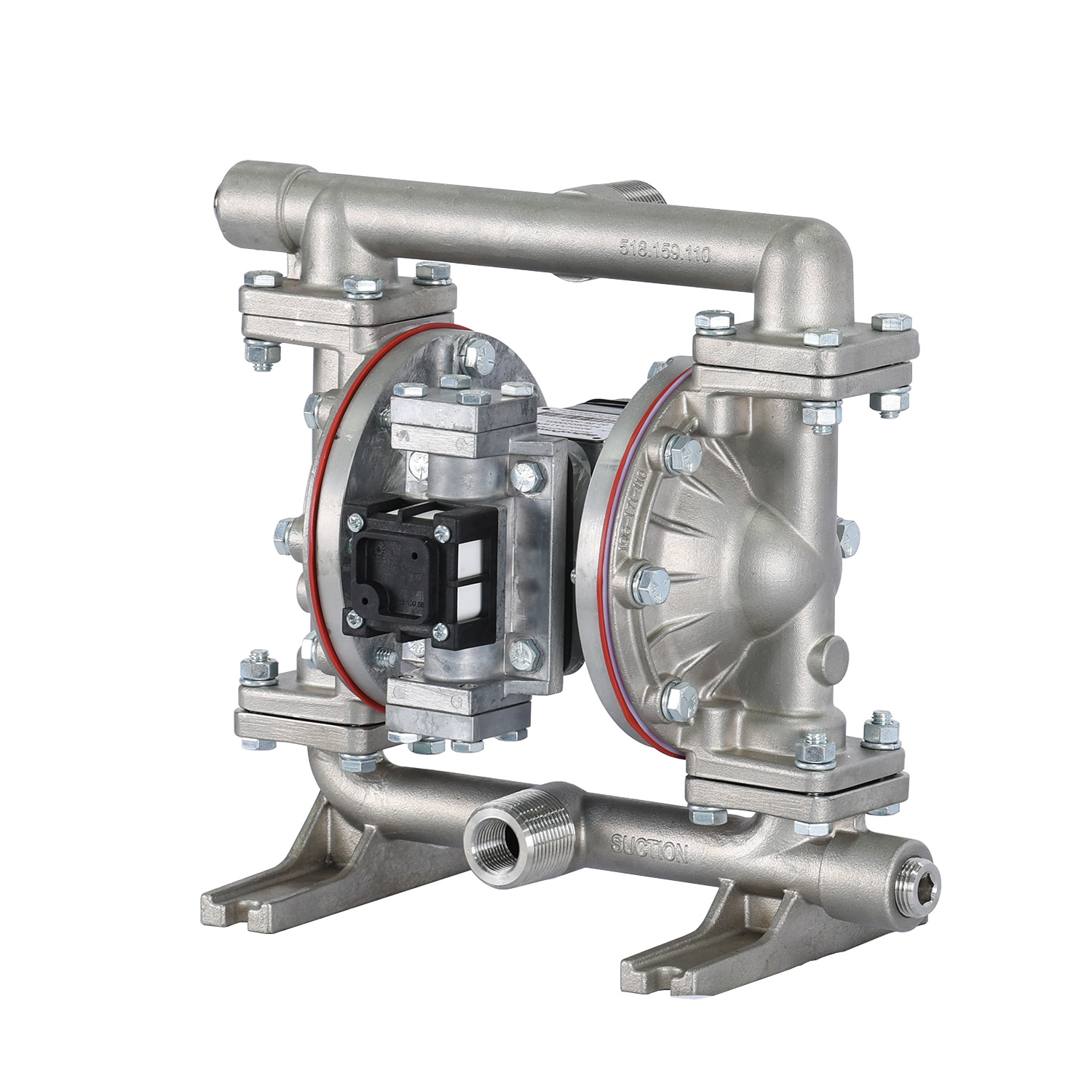

# Understanding the Diaphragm Pump Mechanism

Diaphragm pumps operate using a flexible diaphragm that moves up and down to create a vacuum that draws fluid into the pump chamber. This mechanism is fundamental for ensuring efficient fluid transfer in various applications, from industrial to agricultural use. To operate this pump safley, it’s essential to understand its parts and how they work together.

The key components of a diaphragm pump include the diaphragm itself, valves, and a drive mechanism, which can either be pneumatic or electric. A correctly functioning pump will have all these elements working in harmony to prevent leaks and maintain optimal performance. Regular maintenance checks are crucial to ensure that these components are not worn out or damaged.

When using a diaphragm pump, always refer to the manufacturer’s guidelines for specific operational instructions. Understanding the unique features of your pump model will help you make informed decisions regarding its operation and maintenance. This knowledge can significantly reduce the risk of accidents or equipment failure.

# Safety Precautions Before Operating

Before operating a diaphragm pump, it is imperative to wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and sometimes face shields, depending on the liquid being pumped. Failure to wear PPE can expose you to hazardous materials, leading to serious injuries.

Additionally, ensure that the pump area is clean and free from obstructions. A cluttered workspace can lead to accidents, such as tripping or spilling hazardous fluids. Establishing a safe perimeter around the pump is also advisable to keep unauthorized personnel at a distance during operation.

Check all connections, hoses, and fittings before starting the pump. Any leaks or loose connections can result in fluid spills or pressure loss, compromising the efficiency of the pump. Always conduct a visual inspection and remedy any issues prior to operation.

# Step-by-Step Operating Procedure

To begin operating the diaphragm pump, first connect all necessary hoses and fittings securely. Ensure that the inlet and outlet connections are correctly aligned to prevent any backflow or leakage. Once everything is secure, turn on the power source or activate the pneumatic system, depending on your pump type.

Gradually open the inlet valve to allow fluid to enter the pump chamber. Monitor the flow rate and pressure gauges closely. If the pump struggles to pull in fluid or exhibits unusual noises, turn off the pump immediately and troubleshoot the issue. This step is crucial to avoid damage to the pump or the fluid system.

After the pumping process is complete, turn off the pump and close the inlet and outlet valves. It’s essential to relieve any remaining pressure in the system before disconnecting the hoses to prevent accidental spills. Always clean the pump and surrounding area after use to maintain a safe and organized workspace.